<< Back | Home | Site Map

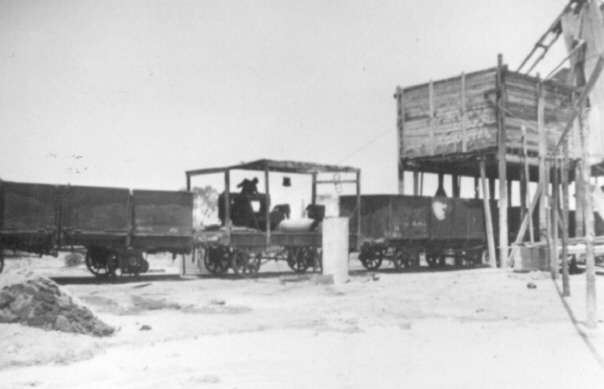

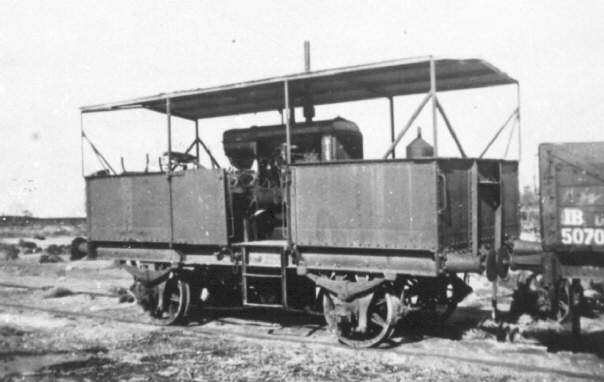

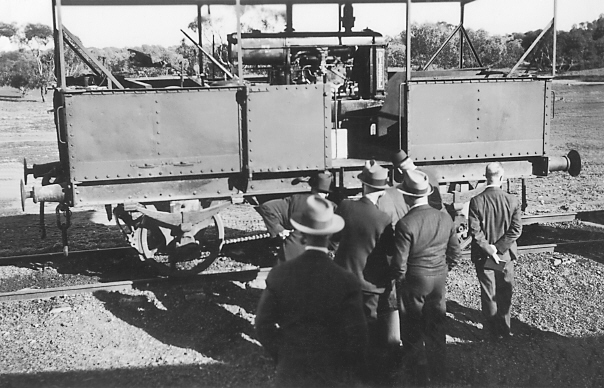

When the Brunswick Plaster Mills Pty. Ltd. began gypsum mining in 1931, their motive power for gypsum haulage was in the form of a Fordson petrol tractor engine and gearbox mounted on the floor frame of an ex-Victorian Railways 11-ton IB Class wagon, with chain drive to one axle. The exact horsepower of the Fordson is unknown but it is believed to have been less than 30 h.p.. A crude shelter covering the length of the vehicle provided the driver with some form of protection from the elements.

It was reported that one of the drivers of the Fordson was a former Victorian Railway's guard who indulged in the practice of using blocks of wood to hold open the points when shunting at the 11 Mile siding. Trucks running through the points damaged the blades and sometimes became derailed. Apparently it was normal procedure not to use the down end points of the loop and at one stage in 1935 it was intimated they be removed, but this was not proceeded with. As output increased, the slow Fordson haulage led the company to investigate a more powerful means of locomotion.

The Brunswick Plaster Mills first form of motive power built in 1931 on the frame of a Victorian Railways IB wagon and powered by a Fordson petrol engine. The sand bag is used for adhesion. Photo: Laurie Birthisel, Bruce McLean Collection

The purchase of "Cleis" (described in the following section) was a failure and the company had to reconsider use of the original Fordson to continue to get the output from the mine to Nowingi siding. It was decided to replace the original Fordson engine with a Dennis truck engine, but this was unsuccessful and not used. The original Fordson engine was replaced and it continued in use until another locomotive could be requisitioned. When the steel IB was purchased (refer to details in following section) the Fordson was retired to stand at the end of the line next to "Cleis". The Fordson was dismantled in 1966.

The remains of the wooden IB were exposed from under a sand drift when water from the gypsum washing plant was diverted to that particular area. The axle box frames and brake hangers can be seen. 24-6-1981. Photo: Bruce McLean

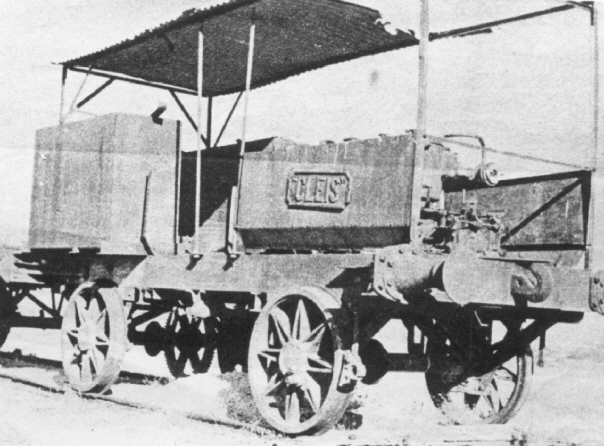

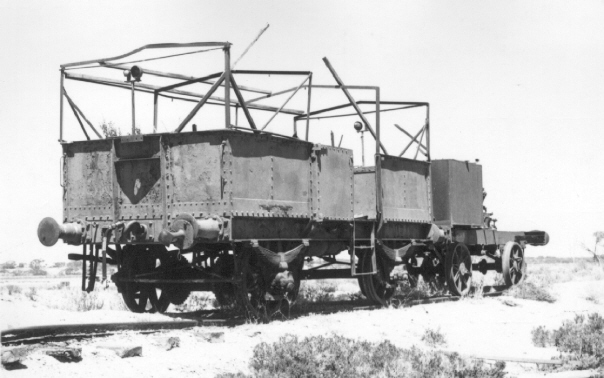

In 1937, the Brunswick Plaster Mills Pty. Ltd. purchased a 0-4-0 locomotive from the Box Hill Brickworks, Melbourne. This locomotive was called "Cleis" and carried plates bearing the name each side. "Cleis" was powered by a 3-cylinder Gardner petrol engine with gear drive to one axle and had the additional facility of side rods connecting to the front wheels. "Cleis" was fitted with a hand brake, a galvanized iron roof supported on a sturdy frame, and buffers. Two large water tanks on each side were provided for engine cooling purposes, the Gardner engine not having a conventional radiator. The weight of the water tanks would also have provided adhesion.

The builder of "Cleis" remains a mystery but it is understood that the builder's daughter was named "Cleis".

"Cleis" in service at the Box Hill Brickworks siding. "Cleis" was a unique "home-made" locomotive that has, through its association with Nowingi, become an object of long standing interest, despite the fact that the majority of its life was spent standing on the Raak Plain as a discarded relic. Photo: Australian Railway Historical Society Archives

"Cleis" was transported to Nowingi on a Victorian Railways flat wagon. To unload, it was necessary to jack "Cleis" up, roll the flat wagon from beneath and then lower to the rails, the operation extending over two days. "Cleis" was then dispatched out along the Millewa South line to the plant "light engine". It apparently became evident almost immediately that it was not going to be suitable for gypsum haulage due to its very low gearing and slowness. There was also reason for concern when the fuel consumption for the 16 mile journey amounted to 44 gallons!

Its unsuitability for heavy haulage was confirmed when the engine broke down at the 11 Mile loop, about 5 miles from the gypsum loader, when hauling its first rake of loaded wagons. According to the late Laurie Birthisel who worked with company as site manager for over 40 years, "Cleis" was considered not worth persevering with and was moved to the end of the railway beyond the gypsum loader where it was declared as being unsuitable for heavy haulage over the distance required. "Cleis" therefore made only one complete journey on the Nowingi to Millewa South line.

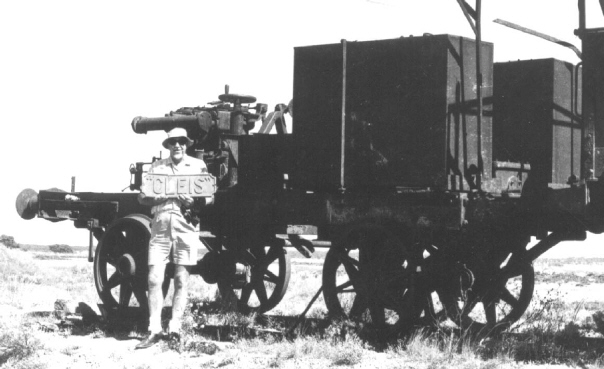

This photographed accompanied articles on "Cleis" appearing the Melbourne "Herald" newspaper on 11-5-1963 and "Australasian Post" magazine on 29-8-1963. "Cleis" was stored at this time still bearing the nameplate. Source: Bruce McLean Collection

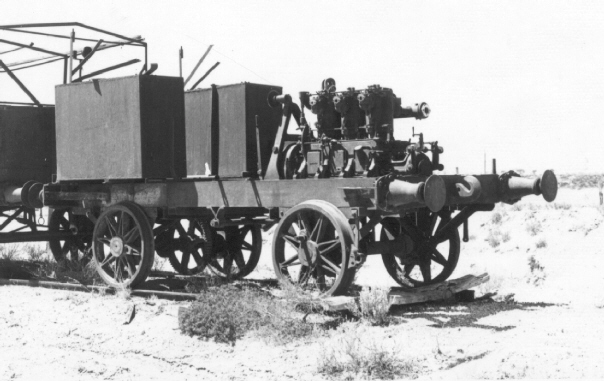

"Cleis" standing on the last rails of the Millewa South line in 1972. The 3 cylinder Gardner engine can be seen quite clearly. Exposure to the salt-laden winds blowing off the Raak Plain have been responsible for the deterioration of some of the features of the locomotive including the roof and panels with the nameplates. Photo: Bruce McLean

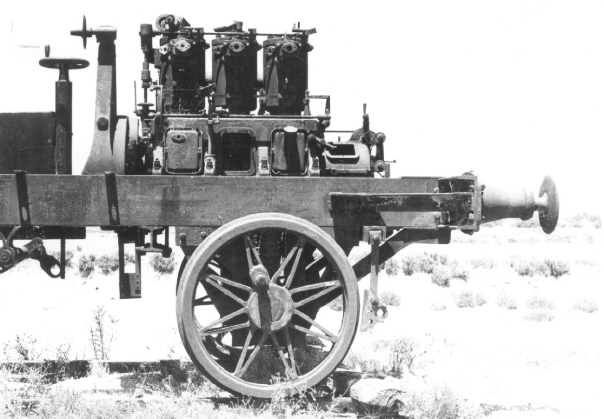

Close up view of the Gardner 3-cylinder engine on "Cleis". Note that "Cleis" is standing right on the end of the Millewa South line. The line was dismantled from this point to the 24 mile station. 18-11-1973. Photo: Bruce McLean

Interior view of "Cleis" showing the 3-cylinder Gardner petrol engine. 18-11-1973.Photo: Bruce McLean

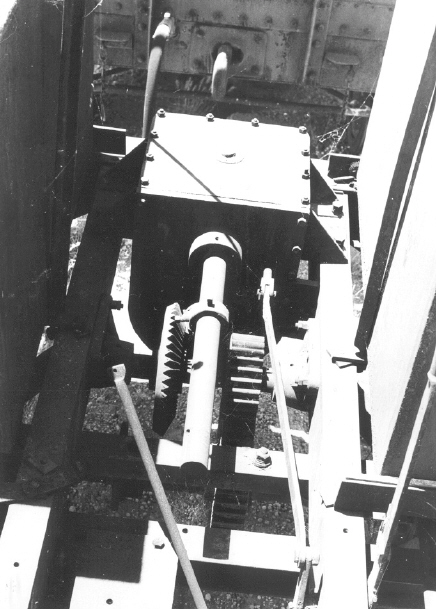

Gearbox and gear arrangement to axles on "Cleis". 18-11-1973. Photo: Bruce McLean

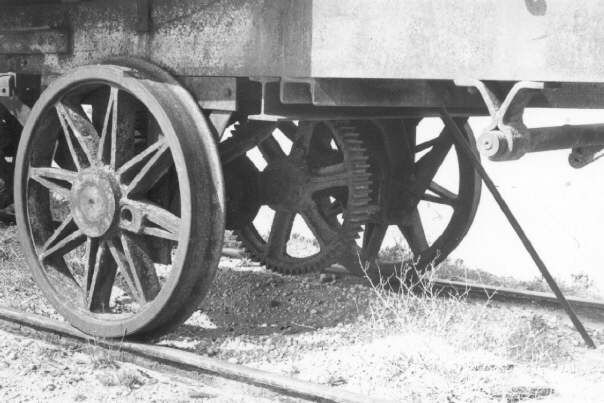

Close up view of the gearing arrangement on the axle and handbrake on "Cleis" 178-11-1973. Photo: Bruce McLean

Note gear on wheel and the hole and bearing for fitting of the side rod. It was this low gearing arrangement and slowness of movement that rendered "Cleis" unsuitable for heavy haulage over the distance required. Photo: Bruce McLean

In July 1963, a journalist from Mildura's "Sunraysia Daily" newspaper wrote a story on a report that the Brunswick Plaster Mills first "locomotive" (known as "Cleis") was to be hauled away and scrapped or put into a railway museum. The newspaper story referred to the locomotive as "The Red Terror" as a result of its rusted appearance following years of sandblasting by copi-borne winds blowing off the Raak Plain as it stood at the end of the remaining portion of the Nowingi towards Millewa South line.

A follow-up story in "Sunraysia Daily" on 7-1-1964 supported the idea that "Cleis" should be preserved at Rio Vista park, Mildura. The article also made reference to the successor to "Cleis", a former Victorian Railways IB Wagon fitted with an engine and the purpose-built diesel locomotive introduced in 1956. The article made a mistake in referring to "Cleis" being dubbed the "The Red Terror" by construction workers when work on the line commenced in 1928. As this history indicates, "Cleis" was purchased by the Brunswick Plaster Mills from the Box Hill Brickworks in 1937 and it proved to be an absolute failure when it ran its first trip at Nowingi.

Noted rail historian, the late John Buckland, is pictured holding one of the nameplates originally attached to "Cleis" on 1-1-1974. The nameplate was salvaged from a nearby rubbish dump by Geoff Pianta when fossicking with the author. Photo: Bruce McLean

"Cleis" was brought forward from the end of the line at Nowingi, given a coat of silver paint, and fitted with a new frame to hold a roof of old galvanised iron sheets, by mine manager Laurie Birthisel for the visit by a group of members from the Australian Railway Historical Society on 1-10-1977. Laurie was with the company when "Cleis" arrived at Nowingi and this was a very proud moment for him when he was re-united with the nameplate. Don Potts had arranged for the plate to be polished, painted and mounted on a wooden plaque. Photo: Bruce McLean

By June 1981, "Cleis" and its mate, the Second IB, were still languishing at the end of the line, the effects of rust starting to show through the silver frost paint applied in 1977.

The late afternoon sun highlights "Cleis" at the end of the line. "Cleis" was shunted forward into the soft, salty ground during loading operations at the nearby stockpile. 24-6-1981. Photo: Bruce McLean

"Cleis" was pulled forward with the IB wagon to stand under the gypsum loader. 7-11-1987. Photo: Bruce McLean

Following the closure of the Nowingi operations, "Cleis" was moved to Express Engineers, Mildura. The move took place between 7-11-1987 and 2-10-1988. "Cleis" was stored with a heap of collectable material by its new owner, Mr. H. Pollard of Express Engineers.

"Cleis" is in there - covered by timber, steel and miscellaneous junk. "Cleis" in its "saved" state, languished in the yard of Express Engineers from about 1987 until 2000 when a new lease on life was given to this historic vehicle. 22-1-1991. Photo: Bruce McLean

The Gardiner three-cylinder engine had attracted his interest and Mr. Pollard sought information on the engine from the English manufacturers to assist with restoration. The railway wheels were removed in 1999 and the sturdy riveted frame fitted with a truck differential and wheels for use as a mobile gypsum crusher for Morello Earthmoving Pty. Ltd., Buronga, New South Wales.

"Cleis" being adapted for a new life at Express Engineers, Mildura. Note the hopper on the rear, the motor and road wheels. 10-4-1999. Photo: Bruce McLean

The thought of the bones of "Cleis" entering a new life in the year 2000 associated with gypsum crushing after spending the majority of its life stored at the end of the Nowingi railway on the windswept Raak gypsum plain, is an irony that has delighted the author.

In 1937 the Brunswick Plaster Mills Pty. Ltd. purchased a steel-bodied 11 ton IB Class wagon No. 6374 from the Victorian Railways and installed in it an International WD40 diesel tractor engine of 40 horsepower. Power was transmitted by chain drive to sprockets mounted on each axle and ballast for extra adhesion was provided by the simple application of fitting steel sheets in each corner of the truck and filling the corners with gypsum. The IB was fitted with a galvanized iron canopy and later, headlights. The wagon cost 100 pounds and the modifications were made at Moreland, Melbourne. The "locomotive" was sent to Nowingi on 2-3-1939 by rail at a charge of two shillings per mile.

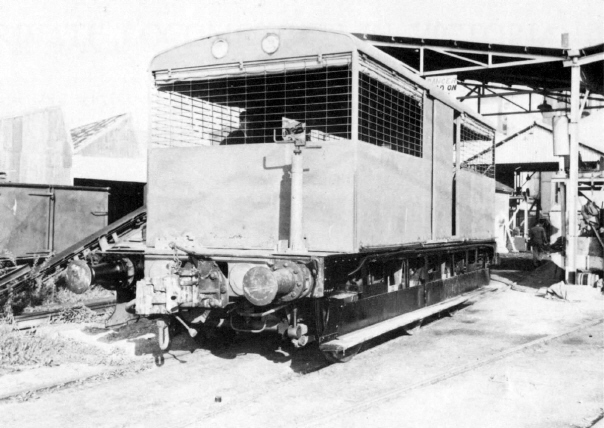

The third form of motive power was also converted from a Victorian Railways IB wagon and had an International WD40 diesel tractor engine fitted. It was used from 1937 to 1956. Photo: Laurie Birthisel, Bruce McLean Collection

The IB class number 6374 was discovered under thick coatings of paint on the side sill on 2-3-1982. The numbers can be clearly seen punched into the steel frame. Photo: Bruce McLean

Commissioners and officials from the Victorian Railways inspect the new steel IB "locomotive" developed by the Brunswick Plaster Mills for hauling gypsum along the Millewa South line. Photo: Puffing Billy Preservation Society Archives

The IB broke three axles over the years but this was overcome by fitting a bigger and wider boss to take the sprockets on the axle. It was further modified by altering the chain drive to one axle only and replacing the leading axle with a standard axle.

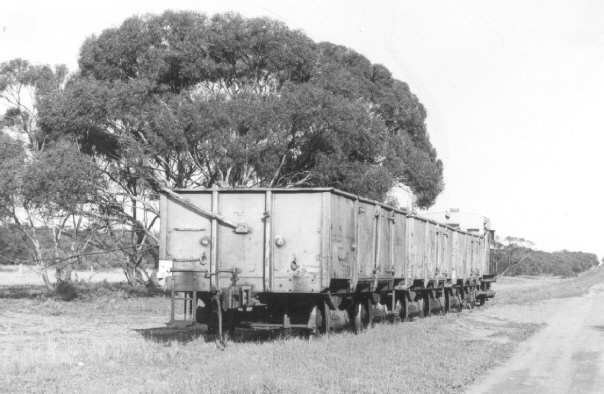

By the mid-1950's, gypsum was averaging 900 tons per week and it became necessary for a more powerful type of locomotive to be obtained. The successful outcome from the manufacture of a larger locomotive with 150 horsepower enabled the steel IB to be retired after a successful career from 1937 to 1956.

The second IB locomotive and "Cleis" abandoned at the truncated end of the Millewa South line in 1972. Photo: Bruce McLean

When the steel IB was replaced by the 0-6-0 Y Loco in 1956, it was placed next to "Cleis" at the end of the track. In this end view of the locomotive taken in 1972, we see the remains of the roof structure with light fittings attached, salt bush growing in gypsum-filled bunkers (to provide adhesion) and the air-hose pipe for brake connection. Photo: Bruce McLean

The steel IB was still largely intact but showing the ravages of increasing rust areas when inspected on 24-6-1981. Photo: Bruce McLean

The haunting scene of "Cleis" and the steel IB standing at the end of the Millewa South line at the Raak Plain gypsum mining area as the shadows draw at the end of a hot summer day. 30-12-1981. Photo: Bruce McLean

Following the close down of gypsum operations and the sell off and removal of the plant and buildings, the IB and "Cleis" were moved forward to stand under the remains of the gypsum loader. "Cleis" was sold to Express Engineers in Mildura, however the IB was not deemed to be of any value to anyone and was cut up for scrap.

The IB locomotive standing under the gypsum loader with "Cleis". "Cleis" was saved but the IB ended up being scrapped. 7-11-1987. Photo: Bruce McLean

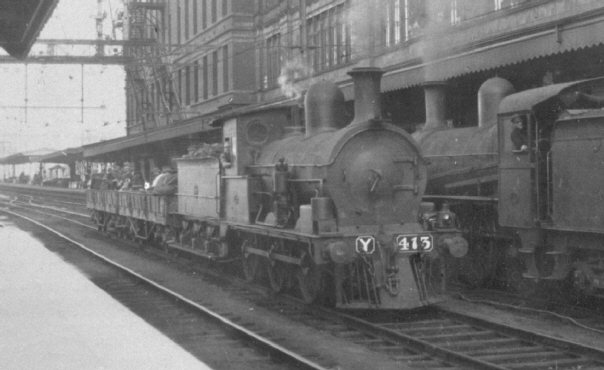

Early in 1956, the Victorian Railways sold the Brunswick Plaster Mills their former Y109 - an old 0-6-0 locomotive built in 1889 by the Phoenix Foundry Company, Ballarat (Builders No. 235). Y 109 (formerly Y413) was withdrawn from service on the Victorian Railways in December 1954, after 65 years of service.

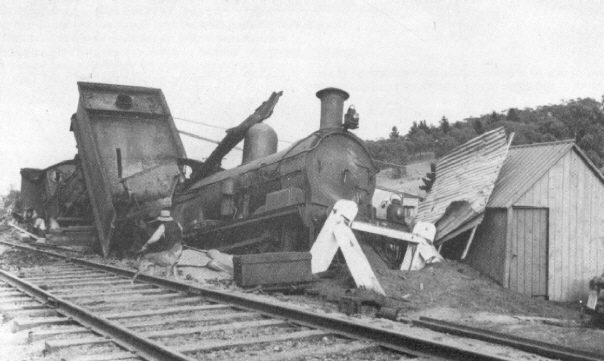

As Y413, this locomotive as the leading engine to A204 on a double-headed goods train, ran out of control down Langi Kal Kal bank at Beaufort and crashed into buffers at the end of a siding into which it had been diverted, on 8-2-1910. Y413 suffered only minor damage although lives were lost in the accident. It was also one of the few Victorian Railways locomotives to work over the private Rosstown Railway during relaying and regarding work in November 1890.

Y413 hard against the buffer stops in a siding at Beaufort. Y413's tender is pitched in the air with A204 pashed up hard under it. 5-2-1910. Y413 (or part thereof) survived to have a successful career in the remote Sunset Country of Victoria. Photo: Victorian Railways

Y413 in better days at Flinders Street Station, Melbourne, with two wagons with way and works materials. Circa 1930. Photo: A.R.H.S. Archives

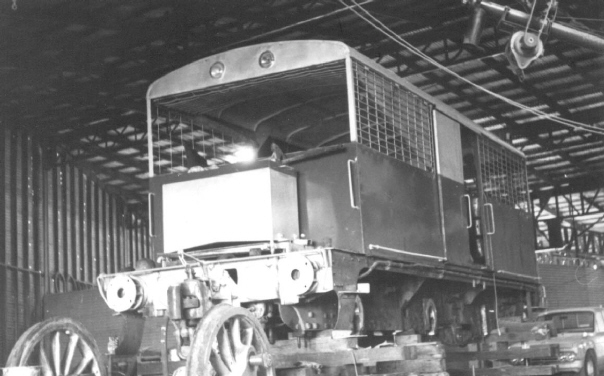

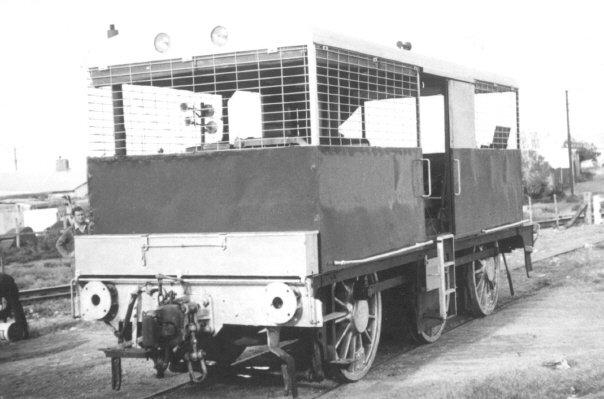

The Brunswick Plaster Mills only required the frame and wheels to which was fitted a General Motors 71 series 6 cylinder 150 h.p. two stroke diesel engine with 130 h.p. continuous rating at 1,6000 r.p.m. and designed for a starting tractive effort of about 16,000 pounds.

A cab was built to completely enclose the engine and driver, who sat sideways near the centre to facilitate operation in either direction. Window openings with welded steel grids extended around the superstructure above waist height, with internal canvas blinds for use in bad weather.

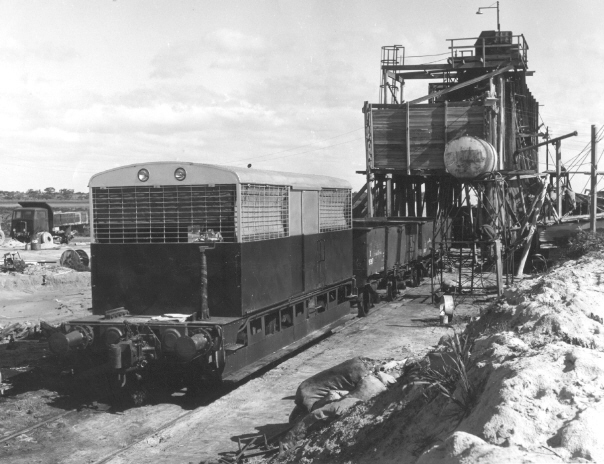

The diesel locomotive constructed for the Brunswick Plaster Mills Nowingi line on the frame of former steam locomotive Y413 (later Y109). Note the inside cylinder castings showing on the front beam. The locomotive is photographed at Moreland before transfer to Nowingi. 1956. Photo: Victorian Railways

The full-length shunter's footboards were retained but were removed in 1972. A single trumpet air whistle was mounted on the cabin roof and twin sealed-beam headlights were fitted at each end.

The locomotive was driven through a conventional 4-speed gearbox with overdrive in top, salvaged from a General Grant tank, and was equipped with a Westinghouse air brake. A small air compressor, belt driven from the engine, supplied air for braking, whistle and sanders. It took about 15 minutes at idle to pump the main reservoir pressure to 75 pounds. The brake was continuous throughout the rake of wagons being hauled. Alterations to the brake equipment and fitting of locomotive-type dual screw transition and automatic couplers were carried out at Newport Workshops. Buffers were originally at each end but in later years removed. The rest of the conversion was carried out by the company's engineers at its Moreland (Melbourne) works.

This portrait of the Y Loco at the Raak Plain gypsum loader shows the locomotive in original condition with the shunters steps and protection from the motion gear. They were removed in 1972. 7-8-1956. Photo: Ted Lawton

Every weekend the Y Loco was left shut down on the curve leading from the Nowingi station yard. This was done for the convenience of the train driver who went home for the weekends (during the week, workers stayed at the 16 mile barracks). It was always a delightful experience to inspect the locomotive in the peace and quiet of the mallee scrub at this remote location. 13-7-1969. Photo: Bruce McLean

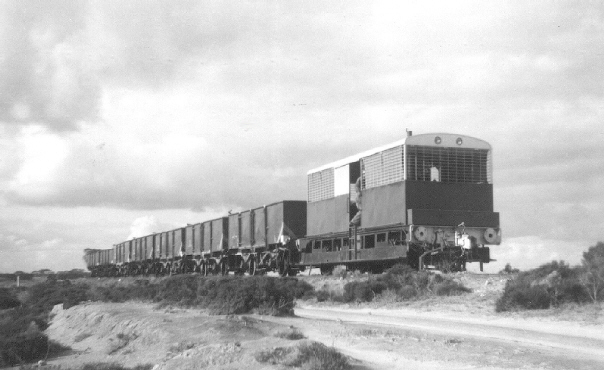

A typical scene of the Brunswick Plaster Mills 0-6-0 diesel locomotive at work hauling empty GY and I/IA wagons from Nowingi station siding to the Raak Plain gypsum loader. The sunset country is big sky country and a harsh environment as depicted in this section of track passing through a saltbush flat. This is a late Sunday afternoon movement on 13-7-1969 in order to have the wagons ready for loading the next morning. Photo: Bruce McLean

A head-on view of the Brunswick Plaster Mills 0-6-0 diesel locomotive built on the frame of former steam locomotive Y413 (later Y109) in 1956. 13-7-1969. Photo: Bruce McLean

The Y Loco stabled on the curve at Nowingi April 1973. Note the shunters steps and motion gear protection has been removed. Photo: Bruce McLean

Side view of the locomotive stabled on the curve leading from Nowingi station ground. This view amongst the mallee scrub is a favourite. April 1973 Photo: Bruce McLean

In August 1973, hinged Perspex windows were fitted to each end of the cabin behind the steel mesh grids. For some reason, they don't extend the full width of the cabin, being off-set to one side, and were a long-overdue facility for driver comfort, giving a measure of protection from rain and wind-borne sand.

The original sandboxes were retained. Sand was obtained by sweeping sand from any one of the numerous sand hills near the line with a broom and then sifting to remove any debris. This procedure became complicated when the sand was wet as they did not have any drying facilities.

The Y Loco made its first journey under its own power from Nowingi to Mildura in the early 1960's. The reason was to replace axle pads. It is not known where this took place, although it would be reasonable to expect that the work would have been undertaken at the steam locomotive depot where all the required lifting equipment and skills would have been available.

After about 16 years of plying the 16 miles between Nowingi station and the Raak Plains gypsum loader, the "Y Loco" as it became known amongst railway enthusiasts, had developed serious problems with its driving wheels. The wheels had worn a groove of the narrow profile of the rail head and this was a dangerous situation that could easily lead to a derailment of the locomotive. The Mildura automotive engineering firm of Tractor & Implements Pty. Ltd. was engaged to undertake the task of replacing the wheels with a new set obtained from the Victorian Railways. Permission was given by the owner of Sunraysia Flour Mills (Mr. A. Anderson) in Lemon Avenue, Mildura to use his siding and undertake the work in the empty shed. This was an ideal situation, and allowed the locomotive to be transferred by rail with minimum difficulty.

The "Y Loco" made its second trip from Nowingi to Mildura under its own power on 18-5-1972.

Wheel off the Y Locomotive showing the "groove" developed from running constantly on the narrow head rail between Nowingi and the Raak Plain gypsum loader. July 1972 Photo: Geoff Pianta

The Y locomotive on blocks and with the wheels removed. This work was undertaken by Mr. N. Couroupis of Tractor & Implements Pty. Ltd. Mildura in the former Sunraysia Flour Mills shed taking advantage of the railway siding connection to the mainline. July 1972. Photo: Bruce McLean

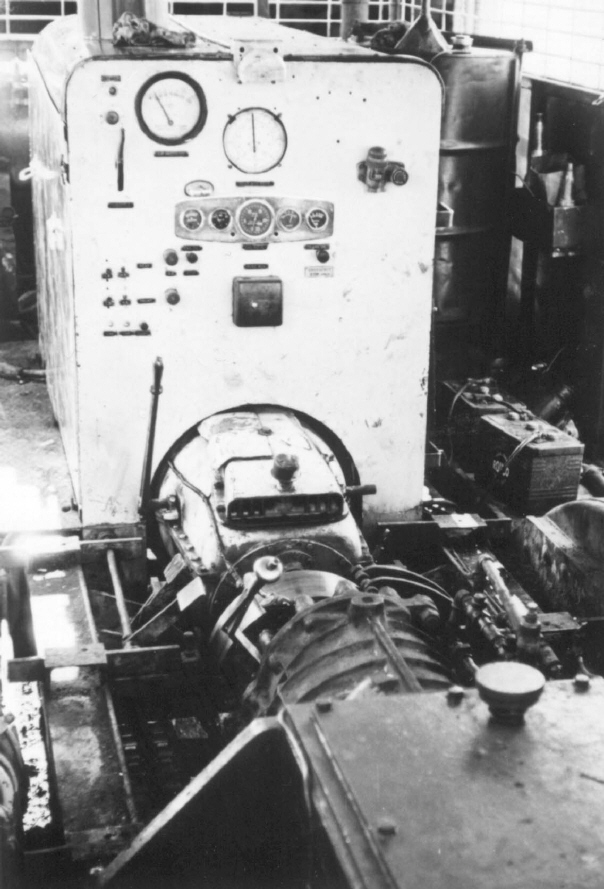

The Y Loco was powered by a General Motors 71 series 6 cylinder 150 horsepower 2 stroke diesel engine with a 4 speed gearbox from a General Grant tank. Photographed during a maintenance overhaul at Mildura from May to July 1972 at Mildura. 12-7-1972. Photo: Geoff Pianta

The opportunity was also taken to give the locomotive a complete overhaul - a job that lasted two months. On 12-7-1972 the locomotive was started up and moved on its new wheelsets from the siding and undertook trials in the Mildura railway yard and former steam locomotive depot sidings.

With work completed, the Y Loco has been moved from the Sunraysia Flour Mills shed before moving from the siding onto the main line for trials. 12-7-1972. Photo: Geoff Pianta

Nick Couroupis (on right) and VR Engineman Robin Davy check the motion gear of the Y Loco before it goes onto the main line for testing. A VR driver was required to be on the locomotive during the testing on 12-7-1972. Photo: Geoff Pianta

The Y Loco ventures onto the mainline with Nick Couroupis driving under the supervision of VR engineman Robin Davy. 12-7-1972. Photo: Geoff Pianta

Robin Davey attends to the staff locked points to enable the Y Loco to move to Mildura railway station for trials on 12-7-1972. The author, in the dark jumper on left, is watching proceedings with keen interest. Photo: Geoff Pianta

The Y Loco has just crossed the Madden Avenue overbridge and reached the home signal at Mildura station yard. 12-7-1972. Photo: Geoff Pianta

The Y Loco has now reached the Mildura station yard and is proceeding down No. 2 road. 12-7-1972. Photo: Geoff Pianta

A meeting with the big boys of the VR locomotive fleet. The Nowingi Y Loco stands in Mildura station yard in the prestigious company of B60 "Harold W. Clapp", B75 and a T Class. 12-7-1972. Photo: Geoff Pianta

A portrait of two of the author's favourite locomotives - B60 "Harold W. Clapp" and the Brunswick Plaster Mills Y Loco. The Y Loco was waiting to commence trials when B60 departed Mildura with a goods train. 12-7-1972. Photo: Geoff Pianta

Testing the Nowingi Y Loco on the old Mildura steam locomotive depot sidings following the replacement of the three wheelsets and a mechanical overhaul. 12-7-1972. Photo: Geoff Pianta

The driver of the Y Loco at his driving station. It was not a comfortable job having to sit on a steel tractor seat in searing heat and chilling cold winds whipped off the Raak Plain on a frosty or wet winter's day. 5-9-1976. Photo: Bruce McLean

At a special ceremony held on 1-10-1977 at the Raak Plain gypsum loader, the Brunswick Plaster Mills 0-6-0 diesel-electric locomotive has just been named Y143 with special Victorian Railways style number plates. Y143 was the original 1889 number of the steam locomotive frame used as the basis for the construction of the diesel when it was built in 1956. Looking on is Mr. Don Potts from the ARHS (Victorian Division), Mr. Laurie Birthisel, manager of the Nowingi operations and Mr. Phil Haley, General Manager of the Brunswick Plaster Mills subsidiary of CSR Limited. Photo: Bruce McLean

Plaque attached to the instrument panel of Y413 on the day of the unveiling of the number plates, by members of the ARHS (Victorian Division) group at Nowingi on 1-10-1977. Photo: Bruce McLean

Now showing with pride its new number plates, Y413 stands on the curve leading to Nowingi station - its usual stabling point on weekends. 18-8-1979. Photo: Bruce McLean

Y413 underwent repairs to the axle bearings on the handbrake end of the engine during July and August 1980. Y413 was moved to the back of the gypsum loader for this work. In this scene we see a workman spreading gypsum in a GY wagon. These wagons were filled from the stockpile to make up for lost tonnage as the replacement VR rail tractor could not pull the same load at Y413. 5-8-1980. Photo: Bruce McLean

By June 1981, Y413 was stored at the rear of the gypsum loader with the Second IB and "Cleis", however it was still operable for use if required. The effects of the salt-laden air were showing on the body and the locomotive was at risk of becoming entirely obsolete due to the replacement M232 being an outstanding success.

This was the sad site on 24-6-1981 when Y413 was relegated to the storage area at the back of the gypsum loader with the Second IB and "Cleis". Photo: Bruce McLean

At some stage between June and December 1981, a short length of track was constructed at the gypsum loader near the workshop and Y413 was moved by slewing a connection from the main line and using M232 to push the engine onto the track section. 30-12-1981. Photo: Bruce McLean

Another view of Y413 on its own track in storage at the Raak Plains loader. 2-3-1982. Photo: Bruce McLean

Portrait of stored Y413 at Raak Plains loader. 2-3-1982. Photo: Bruce McLean

By 1984, the decision was made to close down the Nowingi operation and dispose of the assets. Arrangements were made with the Australian Railway Historical Society in Melbourne to preserve Y413. Y413 was given a fresh coat of blue paint and placed back onto the mainline track in July 1985. The side rods and number plates were removed and M232 was attached ready for the day when it would begin its return journey from its Mallee Sunset Country experience.

Y413 painted up, side rods removed and transferred from its isolated track onto the "main line", in preparation for transfer. Raak Plain works, Nowingi, 9-7-1985. Photo: Bruce McLean

Y413 was moved from the Raak Plain loader to the Victorian Railways siding at Nowingi in March 1986. The afternoon sun catches Y413 as X40 on the up "Sunraysia Fresh" express goods train passes. 26-3-1986. Photo: Bruce McLean

After many months standing at Nowingi, Y413 was finally picked up for transfer to Ouyen. On 17-7-1986 Y413 was attached to another goods train for transfer to Ballarat, however the auto coupler collapsed whilst in transit near Nunga, just south of Ouyen. The loco was returned to Ouyen and stored on the stockyards siding awaiting a decision on repairs and transfer.

The auto coupler at No.2 end collapsed during transit near Nunga on 17-7-1986. The auto coupler had been fitted to the end sill of the old Y Class locomotive chassis where the coal tender linkage arrangements would have been. Over the many years of working in the salty atmosphere at Nowingi, the stress of travel on the main line would have been too much for the coupler attachments. Ouyen. 20-7-1986. Photo: Bruce McLean

Y413 was now stored on the stockyards siding at Ouyen pending a decision on its repairs and transportation. 20-7-1986. Photo: Bruce McLean

After a period in storage on the stock sidings Y413 was moved to the former Pinsch Gas/Rail Motor siding at the down end of Ouyen station platform. 26-4-1987. Photo: Bruce McLean

Y413 was transferred to Ballarat by road transport in 1990 where arrangements had been made with the Australian Railway Historical Society for the locomotive to be used in the restoration of preserved sister locomotive Y112 which had earlier been retrieved from a plinth outside the Ballarat Civic buildings. Y413 ended up at the State Electricity Commission siding where Steamrail (Ballarat Division) was based.

Y413's body sits on the ground in the background at the Steamrail (Ballarat Division) site at the SEC Siding. In the foreground is the frame of Y112 (Y419 - 1889 Number). The wheels and other components from Y413 that were suitable for use in the restoration of Y112 was the reason for the transfer to Steamrail. 28-1-1991. Photo: Bruce McLean

RT6 with a rake of empty wagons bound for the Raak Plain gypsum loader. July 1972. Photo: Geoff Pianta

Victorian Railways rail tractor RT 6 has passed over the three track level crossing at the down end of Nowingi station reserve after completing shunting requirements. July 1972. Photo: Geoff Pianta

Work was required on the leading axle bearings of Y413. Mr. Adrian Goodwin, who had replaced Mr. L. Birthisel as the site manager at the gypsum mine, undertook the repairs in association with Mildura motor engineer Mr. N. Couroupis, during July and August 1980. Y413 was moved to the rear of the gypsum loader while this work was undertaken and Rail Tractor RT28 was hired by the company to maintain the gypsum rail traffic to Nowingi siding. The rail tractor could only push a maximum of three loaded wagons from Sunset siding to Nowingi station.

RT28 propels three loaded GY wagons between Sunset Siding and Nowingi on 5-8-1980. Photo: Bruce McLean

This late afternoon picture shows RT28 pushing three loaded GY wagons near the point where the overhead power cables pass over the line, near Nowingi. The rail tractors were the only motive power that could operate on the line with departmental approval, otherwise a W or Y class locomotive would have been able to haul longer and heavier loads of gypsum. 5-8-1980. Photo: Bruce McLean

The problems being experienced with the 1956 locomotive Y413 during 1980 led CSR to consider two options - move the gypsum by road from the Raak Plain loader or find a replacement locomotive. The track was not any in condition to gain approval for VicRail to provide motive power, however, shunting locomotive M232, built at Newport Workshops in 1959, was offered to the company and purchased.

M232 is shown in company with sister engine M231 at Newport Workshops circa 1963 in their original red color scheme. Photo: Courtesy RB

M232 left Melbourne on 7-1-1981 attached to a goods train but the long run resulted in severe wearing of the side-rod bushes on the engine end wheels and the locomotive was detached at Woomelang on 8-1-1981.

M232 at Woomelang on 9-1-1981 after being red-carded with damaged side-rod bearings during its transfer from Newport Workshops to Nowingi on 8-1-1981. Photo: Bruce McLean

M232 was placed in No.4 road and presented an unusual site in the Woomelang yard with searing hot north winds giving the diminutive locomotive its first taste of what would be its future working environment.

Far away from its former home and workplace at Newport Workshops, M232 sits in the yard at Woomelang waiting for repairs during its long journey to a new home at Nowingi. 9-1-1981. Photo: Bruce McLean

The Mildura loco-foreman removed the side-rods on 12-1-1981 and sent them to Ballarat Workshops for repair. In the meantime, M232 was brought to Ouyen by a goods train and stabled in the former Pintsch gas/rail motor siding on 13-1-1981. The side-rods were refitted on 27-1-1981 and M232 was then towed to Nowingi, arriving at 7 p.m. that night. The following day it was towed by Y413 to the Raak Plains terminus and workshops and the drive-shaft reconnected and repairs to the radiator, generator and batteries undertaken.

On 30-1-1981 M232 was tested with five loaded trucks from Nowingi and overheated between the 4 and 6 mile posts. As a result the radiator and fan belts were replaced and there was no further trouble. When changing direction a loud bang was made and this was discovered to be a broken spring. Other faults included the water temperature gauge not working, air leaking from the reversing lever, cracks on the front and rear automatic coupling mounts and the generator not working.

At 6 p.m. on Monday 2-2-1981, M232 made its first return run with eight loaded GY wagons.

M232 with eight loaded GY wagons on its first trial run from the Raak Plain loader to Nowingi. 2-2-1981. Photo: Bruce McLean

Although lighter in weight than Y413, the M with its torque converter had little difficulty in hauling the load and no wheel slip was observed. The average speed for the return trip with Y413 was 6 m.p.h. but M232, with the same top speed of 12 m.p.h. ran with an average speed of 9 m.p.h. and reduced the round trip time by about an hour.

This first run was also history in the making as M232 crossed Y413 at Sunset Siding - the only instance known to the author of two trains working the Nowingi line since its construction in 1928.

M232 has arrived at Sunset Siding for an historic cross of trains with Y413. Y413 hauled its train of empty wagons from Nowingi and has run around at the loop so that it will propel the wagons to the loader. M232 has cut off from its rake of wagons and will run around the loop when Y413 has cleared. 2-2-1981. Photo: Bruce McLean

M232 with driver F. Mabey at the controls, runs through the loop siding. The locomotive will then attach to the wagons and propel them to Nowingi siding. 2-2-1981. Photo: Bruce McLean

M232 has attached to its loaded wagons and will propel them to Nowingi station sidings. 2-2-1981. Photo: Bruce McLean

It was proposed that M232 would operate the section of line between Sunset Siding and the Raak Plains loader, propelling loaded trucks and pulling empties, whilst Y413 would work between Sunset Siding and Nowingi propelling loaded trucks and pulling empties. The success of M232 and its approval by the driver saw M232 rostered on through trips. It was then planned to effect repairs to Y413's running gear and use the locomotive as a back-up to M232.

M232 was the second of two shunting engines constructed at Newport Workshops in 1959. It was powered by a 150 horsepower GM 6-71 engine with an Allison hydraulic converter and capable of a top speed of 12 m.p.h..

M232 at the Raak Plain loader. The M Class locomotive performed very well and Y413 was relegated to the storage area at the back of the loader. Note the lights fitted to the roof of the locomotive for working at night. 24-6-1981. Photo: Bruce McLean

M232 leads another load of gypsum from the Raak Plain loader towards Nowingi. The line here crosses the salty Raak Plan with a length of discarded rusty rail lying near salt bushes to illustrate the harsh conditions this line had to endure. 24-6-1981. Photo: Bruce McLean

M232 passes the letterbox provided at the company house located to the right of the scene. This point is the eastern edge of the CSR gypsum lease. 24-6-1981. Photo: Bruce McLean

M232 showing signs of its working life in the mallee as it stands at Nowingi during shunting operations on 15-9-1981. Photo: Bruce McLean

Driver Fred Mabey at the controls of M232. Fred Mabey was also a steam enthusiast and during his life has been associated with both steam locomotives and steam-powered paddleboats. 29-6-1983. Photo: Bruce McLean

The author at the driving controls of M232. When gypsum mining ceased at Nowingi, there was an irony with the author's windcheater in that the future fate of M232 was its transfer into the ownership of Steamrail Victoria. 29-6-1983. Photo: John Page

With the decision made to close down the Nowingi operation and dispose of the assets, arrangements were made with the Ballarat Division of Steamrail Victoria to take diesel locomotive Y413 to salvage the wheel sets to restore steam locomotive Y112, preserved in Ballarat by the Historical Society at the Ballarat Civic Centre).Y413 was prepared for transfer with the side rods removed and attached to M232 for transfer to Nowingi.

M232 stands attached to Y413 in preparation for transfer to Nowingi for Y413 to be hauled by a V/Line freight train to Ballarat. 9-7-1985. Photo: Bruce McLean

In closing down the Nowingi gypsum operation, CSR Limited commenced to remove the large stockpile near Nowingi station reserve. In April 1987, locomotive M232 was brought to the Nowingi end of the line and was used as a shunting locomotive for loading of washed gypsum into V/Line and Australian National bogie open wagons. The wagons were shunted to the stockpile area for loading then propelled to the V/Line siding for pick up.

M232's number plates were stolen during a visit by a special train of railway enthusiasts on 31-5-1987.

After transfer by rail to Ouyen, where M232 was noted on 4-1-1988, it was taken by road transport to the Steamrail depot at Newport Workshops where it assumed a new life under its third owners, but this time, instead of being in the salty wind of the Raak Plain and dust of the Sunset Country, M232 was within a whisker of its birthplace.

With the stockpile depleted, M232 was stabled on the CSR siding at Nowingi, having been sold to Steamrail Victoria. Wagons loaded with the last of the washed gypsum can be seen on the background. Note that the number plates off M232 are missing, having been stolen during a railway enthusiast visit to Mildura in June 1987. 7-11-1987. Photo: Bruce McLean

By 4-1-1988, M232 had been transferred to Ouyen and stabled on the Way and Works siding waiting transfer by road to the Steamrail depot at Newport. Photo: Bruce McLean

M232 at the Steamrail Victoria depot on 6-11-1988 after transport from Ouyen by road transport. M232 was back at the place of its birth, Newport Workshops, however it was now in possession of its third owner. Photo: Bruce McLean

| << Back | Home | Site Map | Copyright © 2003 Bruce McLean, All Rights Reserved |